Here we outline the top ways that construction companies (or those self-employed) can ensure a safe working environment.

This is not an exhaustive list and should not intended to be a substitute for following all OSHA requirements. You must follow those to be in compliance. Additionally, you can request a confidential, no-cost OSHA safety and health consultation to create a hazard-free workplace.

1.) Utilize Proper Fall Protection

Falling from high places accounts for most construction injuries and deaths. And according to the OSHA booklet “Falling Off Ladders Can Kill: Use Them Safely,” falls are the leading cause of death in construction and every year falls from ladders make up nearly a third of those deaths.

The rest of the falls that occur are usually associated with wall openings, holes in the floor, scaffolding, roofs or open edges.

To prevent these falls, it’s important that construction sites have proper fall protection in place.

Some best practices for fall prevention include:

- Install guardrails.

- Follow safe scaffolding guidelines.

- Avoid using a ladder if you’ll need to hold heavy items while on it, it won’t be stabilized, if you’ll be working at that height for a long period, or if you’d need to stand on the ladder sideways.

- Consider using personal fall arrest systems for roof workers and provide a harness for each worker who needs to tie off to an anchor.

- Choose the right equipment for the job. Whether that’s beamers, retractables, rope-grabs, butterfly anchors, etc. the most important thing is that the equipment chosen aligns with the task for keeping workers safe.

- Remove anything that may lead to a slip or trip.

- Keep areas with holes off limits and cover unprotected edges.

2.) Keep a Clean, Hazard-Free Construction Zone

On-site construction managers have an obligation to keep construction zones safe for their workers. This means a sweep of the area to look for any debris or hazard that might impede someone from doing their job safely. Here is how to keep a hazard-free construction zone:

- Keep all walkways free of messes, spills, debris or cords. Anything that could cause someone to trip and fall need to be removed.

- Store large materials properly. Out-of-the way areas should be designated for storing tools and materials until they are needed. Anything that could fall should be laid flat or secured appropriately.

- Remove any protruding nails.

- Have containers ready for the disposal of waste material.

- Scan the site regularly for cleanliness or to tidy up anything that looks out of place.

- Use signage to keep unauthorized personnel out of specific work zones.

- Keep specific equipment away from other materials that could start a fire or put someone at risk of electrocution.

3.) Provide Personal Protective Equipment

The purpose of personal protective equipment in the construction industry is to minimize hazardous risks such those associated with chemicals, electricity, machine use, loud noise, falling debris, etc. It is imperative that construction workers are provided with proper protective equipment for the job they will be performing.

Some of the most used PPE that should be readily available include:

- Gloves

- Safety Glasses

- Steel-toed boots and/or Slip-Resistant Shoes

- Earplugs/Earmuffs

- Hard Hats

- Respirators

- Full Body Suits

Not only should this PPE be on-site and ready to go, but workers also need to be trained on how to use each item properly and know under what circumstances which type needs to be used. Consult OSHA’s publications on personal protective equipment for specific details.

4.) Train Workers and Reinforce Safety Standards

No matter how big or small a construction company is, it’s important that every person is committed to following proper safety practices and holding others accountable to those protocols as well.

This starts from the top in showing that a safe working environment is of utmost importance. Safety training should be implemented to educate workers on how to avoid dangerous situations, keep areas clean, and how to effectively use PPE to stay safe.

Over time, it’s important that construction managers and workers never get complacent and continue to monitor that safety standards are being implemented at all times.

More about training requirements and resources can be found here, as well as a voluntary outreach training program provided by OSHA that provides additional training for workers and employers as an extra layer of understanding of how to keep construction environments as safe as possible.

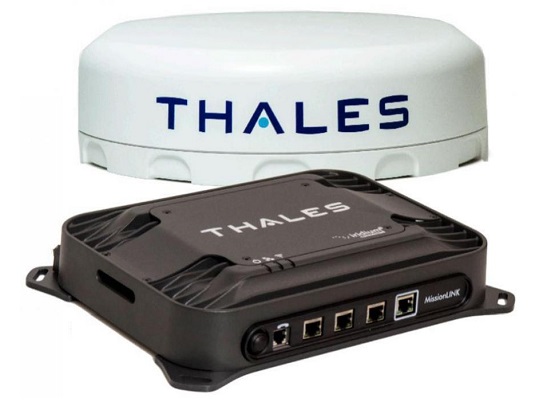

5.) Have Proper Communication in Place

One of the most important parts of maintaining a hazard-free construction environment is effective communication. This construction industry case study shares how communication plays a vital role in a construction project getting done correctly and safely with the expected timeframe.

Two-way radios are essential for effective communication in collaborative work such as construction. However, many construction sites are out of cellular range. In this case, it’s imperative that workers have access to satellite devices to stay in contact. A satellite phone with push-to-talk capability is ideal and some sites may need a device that provides satellite internet, as well.